Microchannel Coils: The Next Generation of HVAC Technology

The HVAC industry has relied on copper tubes and aluminium fins for decades. But as systems demand higher efficiency, lower refrigerant use, and more compact designs, a new technology has stepped in: the microchannel coil. These coils are changing the way air conditioners, chillers, and refrigeration systems are built, offering clear advantages over traditional coil designs.

In this blog, we’ll explore what microchannel coils are, how they work, and why they’re becoming the preferred choice for modern HVAC applications across the GCC and Middle East.

What Are Microchannel Coils?

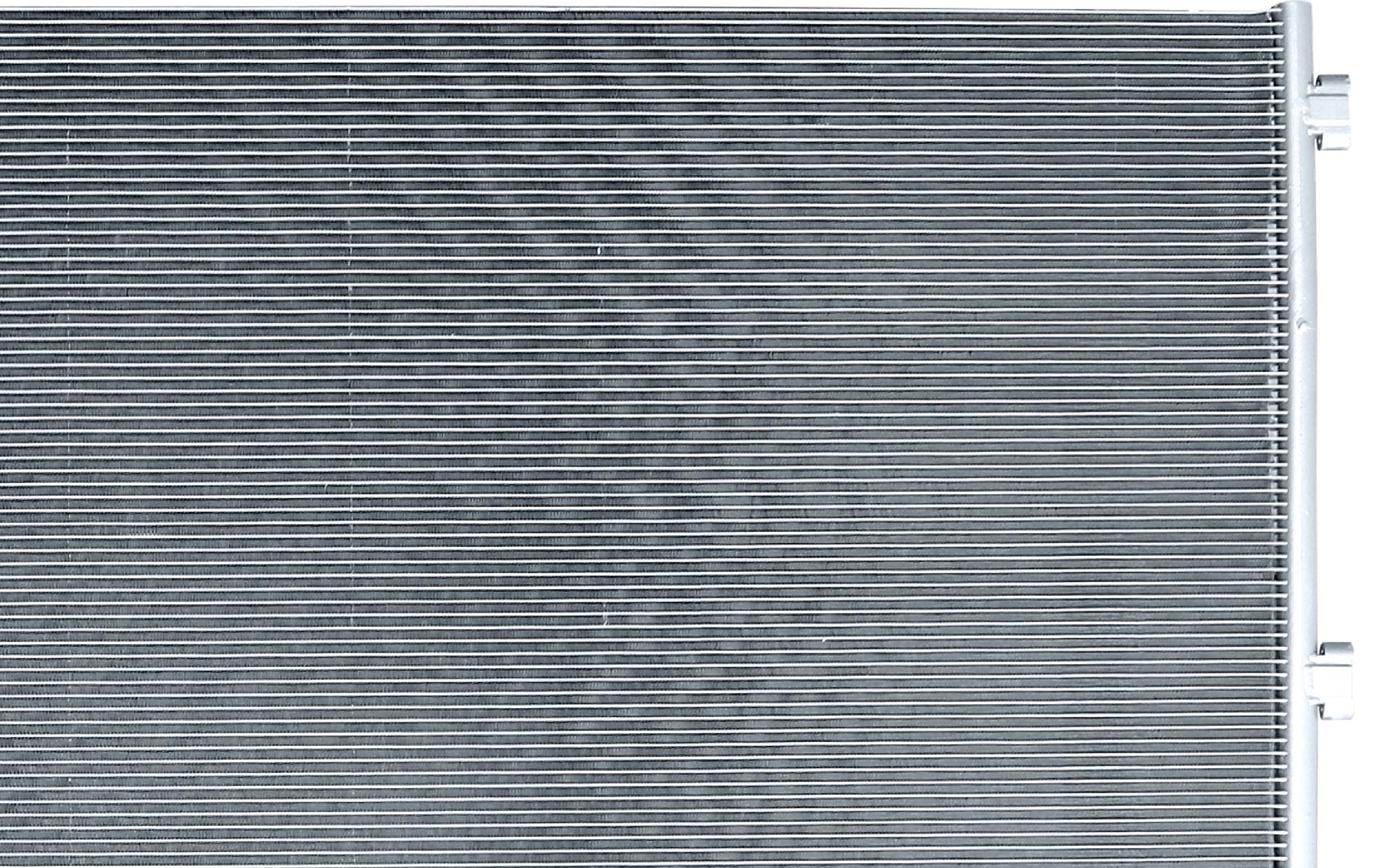

A microchannel coil (MCHX) is a type of heat exchanger made from flat aluminium tubes that contain multiple tiny channels. These tubes are paired with aluminium fins and headers, creating a compact but highly efficient design. By maximizing surface area for heat transfer while minimizing material use, MCHX coils deliver better performance with less refrigerant compared to conventional coils.

How Do Microchannel Coils Work?

The principle is simple but effective:

1. Refrigerant flows through the micro-sized channels inside the flat tubes.

2. Air passes over the fins attached to these tubes.

3. Heat is exchanged more efficiently thanks to the increased surface contact.

This design not only improves heat transfer but also reduces the overall refrigerant charge by up to 40%, making systems more sustainable and cost-efficient.

Advantages of Microchannel Coils

- Higher Efficiency: Greater surface contact means improved heat transfer.

- Lower Refrigerant Use: Reduces environmental impact and running costs.

- Lightweight & Compact: Smaller footprint compared to traditional coils.

- Durability: All-aluminium construction reduces the risk of galvanic corrosion.

- Recyclability: Easy to recycle at end-of-life, supporting sustainability goals.

Where Are Microchannel Coils Used?

Microchannel technology is increasingly applied across HVAC systems:

- Air Conditioners: Widely used in split units and packaged systems for better cooling efficiency.

- Chillers: Helps reduce refrigerant charge while improving capacity in large installations.

- Refrigeration Systems: Ideal for supermarkets, cold rooms, and display cases.

- Automotive & Transport Cooling: Common in vehicles and transport refrigeration due to their compact size and durability.

Why Microchannel Coils Matter in the GCC and Middle East

The climate across the GCC demands cooling systems that can run efficiently in extreme heat while keeping energy consumption in check. Microchannel coils provide a significant advantage by lowering operating costs, extending system life, and supporting regional energy efficiency initiatives. Their corrosion resistance also makes them well-suited for coastal environments where salt-laden air can damage traditional copper-aluminium coils.

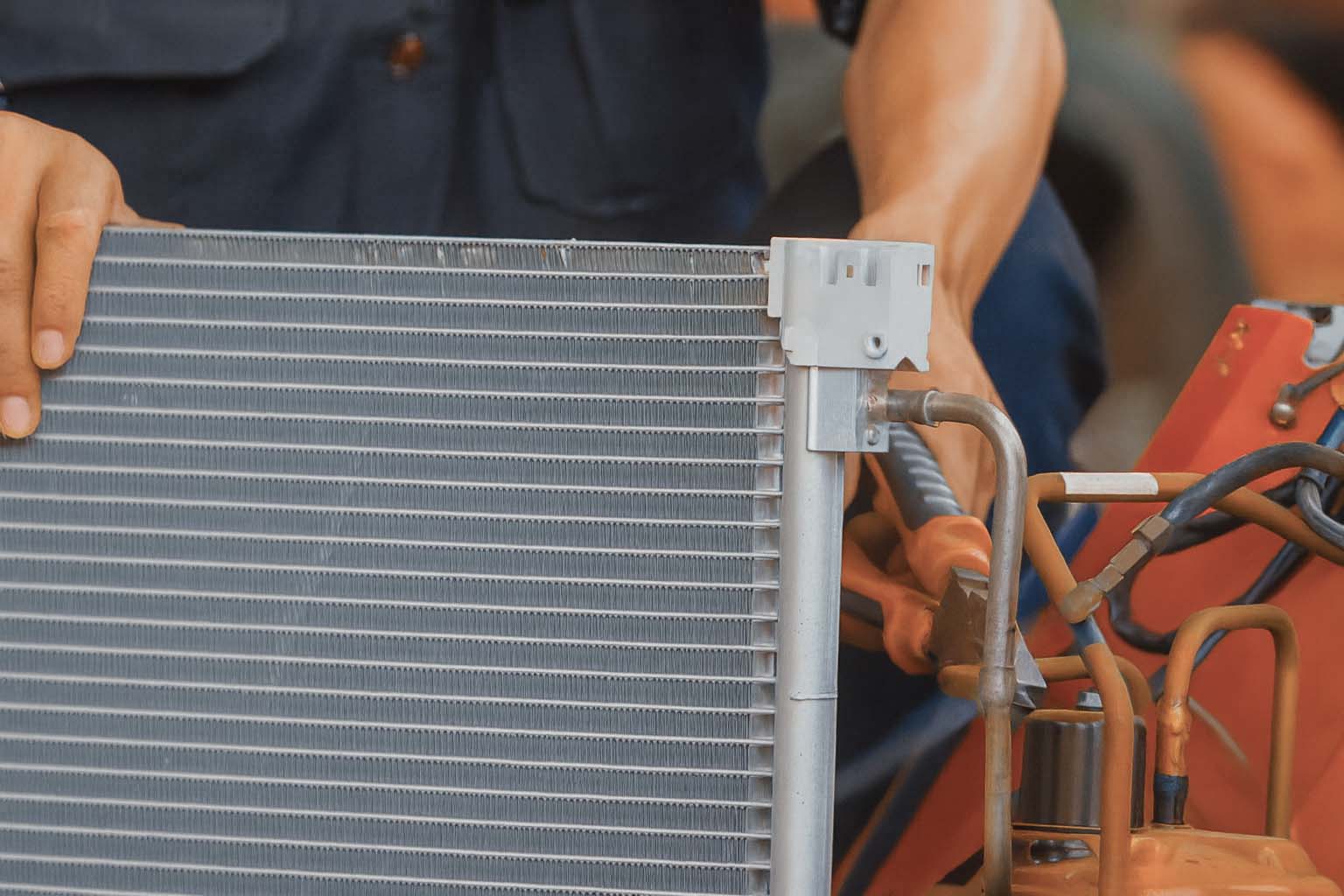

Retrofitting and Coil Replacement

One of the biggest advantages of microchannel coils is that they can replace older copper-aluminium designs in existing systems. Retrofitting with MCHX technology not only boosts efficiency but also reduces refrigerant use, making it a cost-effective upgrade for chillers, packaged units, and air conditioners.

Microchannel coils represent a major step forward in HVAC technology. By delivering higher efficiency, lower refrigerant use, and longer-lasting performance, they are quickly becoming the standard choice for modern systems. From high-rise buildings to industrial plants, they help meet the GCC and Middle East’s growing demand for sustainable and reliable cooling solutions.

For consultants, contractors, and facility managers looking to upgrade or specify new systems, microchannel coils offer clear advantages that translate into real-world savings and long-term reliability.