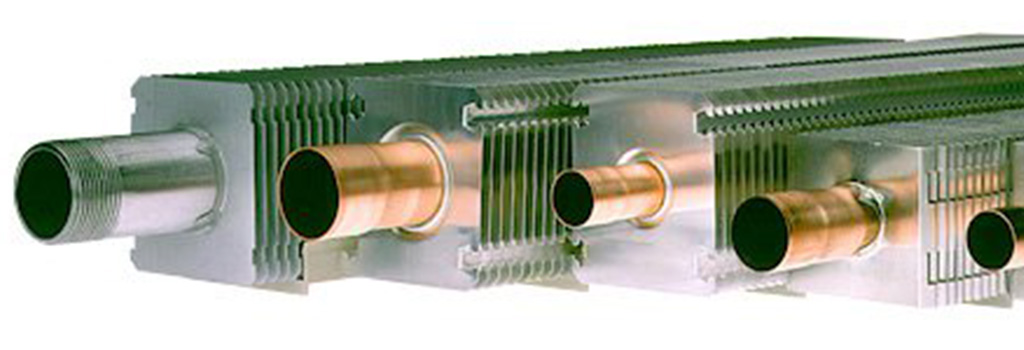

Bare Tube Heat Exchangers

What are Bare Tube Heat Exchangers?

Bare Tube Heat Exchangers are robust devices used for transferring heat between two fluids. Unlike finned tube heat exchangers, bare tube designs rely on the direct surface area of the tubes for heat transfer, making them ideal for applications where high temperatures or airborne particles are a concern.

Key Features of Dolphin Bare Tube Heat Exchangers

1. High-Temperature Performance

- Designed to operate efficiently at temperatures over 300°C

2. Particulate Resistance

- Ideal for environments with airborne particles like fibers, oil, or dust that may obstruct coil face areas

3. Specialized Applications

- Specifically manufactured for hospital, clean room, or pharmaceutical applications

4. Customizable Configurations

- Available in different diameters, thicknesses, and materials to suit specific requirements

5. Durable Construction

- Built to withstand harsh industrial environments and high pressures

6. Easy Maintenance

- Simple design allows for easy cleaning and tube replacement

7. Efficient Heat Transfer

- Optimized tube arrangement for maximum thermal efficiency in challenging conditions

Applications

Dolphin Bare Tube Heat Exchangers are ideal for various industries and applications:

- High-Temperature Industrial Processes

- Pharmaceutical Manufacturing

- Hospital and Healthcare Facilities

- Clean Room Environments

- Oil and Gas Processing

- Chemical Manufacturing

- Food and Beverage Production (high-temperature processes)

- Power Generation

- Waste Heat Recovery

Why Choose Dolphin Bare Tube Heat Exchangers?

- Expertise: With over 38 years in the heat transfer industry, we bring unparalleled knowledge to every project.

- Customization: Our engineering team can tailor solutions to meet your specific heat transfer requirements, even in the most challenging environments.

- Quality Assurance: All our heat exchangers undergo rigorous testing to ensure reliability and performance under extreme conditions.

- Comprehensive Support: We offer design, fabrication, installation, and maintenance services.

- Innovation: Continuous investment in R&D ensures our heat exchangers incorporate the latest advancements in thermal technology for high-temperature and particulate-rich applications.

Design Capabilities

Our design process includes:

- Utilization of advanced mechanical design software

- Generation of complex designs for various operating conditions, including high-temperature environments

- Production of optimized solutions for particulate-rich atmospheres

- Creation of detailed fabrication drawings using specialized software

Material Options

We manufacture heat exchangers using a wide range of materials to suit your specific needs and temperature requirements:

- High-Temperature Alloys

- Stainless Steel

- Nickel Alloy

- Inconel

- Hastelloy

- Titanium

- And more, based on your specific application

Fabrication Facilities

Our state-of-the-art fabrication facilities include:

- CNC Drilling for Tube Sheet Drilling

- Orbital Welding Machine for Tube to Tube Sheet Welding

- Microprocessor-based Telescopic Expansion Machine for Tube to Tube Sheet Expansion

Installation and Maintenance

Our team of skilled technicians ensures:

- Professional installation tailored to your facility’s needs, including clean room and pharmaceutical environments

- Regular maintenance to keep your heat exchangers operating at peak efficiency, even in high-particle environments

- Quick response to service requests, minimizing costly downtime

The Dolphin Advantage

Choosing Dolphin for your Bare Tube Heat Exchanger needs means benefiting from:

- Cutting-edge technology in heat transfer solutions for extreme conditions

- Commitment to efficiency and reliability in high-temperature applications

- Comprehensive after-sales support

- Tailored solutions for your specific industry, including healthcare and pharmaceutical sectors